At

first, when we were told we had to do a realistic representation of

an object my initial thoughts went to either a character statue or

some kind of Star Wars model. We were told it was a good idea to do

something we would be passionate about as it would be easier to model

something we liked in greater detail. A Hulk statuette and the

Millennium Falcon both went as initial ideas until I realised they

were far too detailed to do within the time frame.

I

decided on a weapon to recreate from one of my most played games of

all time: Guild Wars 2. It's not my absolute favourite weapon

visually in game but it's near the top. The others above it were

either far too detailed or have crazy particle effects which I

wouldn't know how to create. This was the object I decided on:

I

went about sourcing these pictures from in game, and first got a good

side and top images to use as references. I then went about figuring

out what real world materials these parts could be made from.

So

it was time to start modelling. I set up my reference images in Maya

and started blocking out the basic shapes. Right from the beginning I

knew how important organisation would be so tried to name all the

pieces as best as I could. Also I tried to fit the references as best

as I could while keeping it really low poly.

Now,

the original in game model had a few of the raised panels on the

sword as normal maps. But Guild Wars is an MMO so objects will be

much lower resolution than what I was looking to create, so I decided

to model all the panels, diamonds and rivets out completely.

I

figured that I would be able to use this base mesh I had created as

the low poly in the end. All of it except the 'brass wing' part which

would have to be sculpted better in zbrush first. So for that part I

created a blocky low poly representation to take to sculpt later.

Next was to make one of each of the final details, give it some

colours for personal clarity of material before exporting.

I

imported the wing mesh first into zbrush and set up a reference image

so I could accurately sculpt the detail into the mesh.

When

that was done I imported all my other bits into zbrush. I learned

here that I should have imported them all together at the beginning

then sculpted the wing in that instance, but more on the problems and

what I learned at the end. Here though, I also learned about

importing meshes that need to be subdivided a lot. When it first came

to subdividing the big parts like the blade, they lost too much shape

through smoothing. So originally, I tried subdividing without

smoothing for the first couple of divisions, then have smoothing on

for the rest but it still didn't give the right look. Some parts were

too jagged, and so I had to go back into Maya and add edge loops

everywhere where I wanted to keep those tight edges. Then I

re-imported into zbrush to subdivide again.

Next

was so start adding the high resolution detail to the meshes. In the

references it's clear that there are a lot of scratches, dents and

some tribal markings which were all made as normals in the original.

I would do the same here but with more detail to make into normals on

my model. I went about finding some free alphas for scratches as well

as making a lot of my own. I learned how to create my own alphas and

made a number of scratches and dents which fit the style I needed by

using a big block of 'clay' in zbrush and using different brush

techniques and finally saving as a depth grab. I did this because I

wanted a bunch of chips and dents for the edges of the metal, and I

couldn't find any around that I liked.

I

added the scratches on layers so I could manage them better later on.

I also then worked on the leather grip. I used the surface noise

initially and added the hatch alpha to that, then increased the

strength to give it a lot of depth to get the desired look. I had to

subdivde this a lot of times before baking the detail. After that was

baked I added more surface noise onto the straps to replicate the

leather look, then baked that as well.

Next

came the tribal alphas. I took the reference image into Photoshop and

then sketched over each pattern in black on a new layer and tidied

up the edges best I could. I then made them symmetrical where

necessary. I then selected the black layer using the wand. I then

increased the radius of the selection by a few pixels, made a new

layer underneath and filled that slightly larger selection with a

medium-dark grey. This was so when printing the alphas they would

have a more beveled, smooth edge in zbrush.

After

all that detailing was complete (and we were up to 32 million polys),

I copied all the parts which needed to duplicated into their correct

positions. For the 'wing' part, I had to go to a lower subdivision in

zbrush and export that as the low poly. The original low poly I had

originally made in Maya was far too blocky and inaccurate.

I

learned during this positioning, that I should have done this first

in Maya. I originally thought it would be easier to import just one

of each piece, detail it and then duplicate that. It probably would

have been easier the other way round. For two reasons: the first was

that the zbrush moving is fairly inaccurate compared to Maya's so it

took longer to position than it should. The second was that now I had

to make sure the low poly Maya version had all the pieces in the

exact same (slightly inaccurate) places. Which was a pain because it

meant I had to decimate the zbrush model to put into Maya so I could

have an accurate copy. I would not have needed to do this step if I

had planned properly. Eventually, I did get it done though, then it

was time for the fun that is UV's.

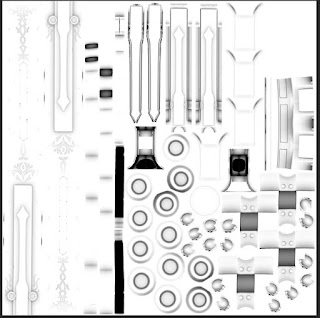

So

I gradually unwrapped each piece and made sure to keep them on the

same sheets as with other pieces of the same material. The leather

handle was an exception, but I stuck it in with the brass wings and

end pieces as there was space. Unwrapping the wings was pretty

painful and time consuming to make sure there was minimal distortion

and the cuts weren't in bad places. It was difficult due to the shape

and the fact that the one I imported was probably one subdivision

higher than I should have used.

I

eventually got them all done. I then optimised the entire mesh. I got

rid of as many unnecessary edge loops as I could, cleaned it up and

managed to get the low poly down to around 18k polys. I could've gone

lower I think if I had managed the wings poly count a little better

earlier on.

Next

was exporting to bake maps. I had the high poly to the lowest I could

get it – around 22 million. I used all the settings as shown in

class in xNormal to create the maps. I had my three high poly meshes

and my 3 low poly all ready to go. I had to do a few (and very

lengthy) bakes of cavity maps to get it all looking ok. For some

reason the ambient occlusion maps came out flat grey and white rather

than had any detail. Luckily the cavity maps worked fine and looked

good.

I

then did some manual editing to the maps before taking into Quixel. I

did the high pass trick on each of the normal maps. I also had to do

some editing bits on some of the channels of the normal maps to get

rid of some weird bits.

I

first imported the brass wings mesh into Quixel and started working

on it. I had it looking really good as you see below. Unfortunately

Quixel crashed at this point and I lost most of the good stuff I had

done here. I usually save very often but you cannot save in Quixel

while editing the alphas. So very annoyed I had a break.

On

that break however I learned on a video somewhere about how you can

import multiple meshes into Quixel at the same time. So I went back

into Maya, grouped the OBJ's and exported as one single OBJ to take

into Quixel. This made it much easier. I decided to make one metal

part of the handle have some detail too which previously didn't have

any. I did this because thought it looked quite boring when it was

plain. I added a hatch pattern in NDO first and turned that into a

normal. I added some wear to it with a soft brush and continued back

into DDO.

I

went about making the brass and leather (again), honestly this time I

didn't do it as well for some reason. I found it hard to replicate

what I had done previously as you see below.

Next

was the 'titanium' parts. First I tried making them steel and

painting some darker oily spots to try and replicate the reference.

But it ended up not looking very good at all. Here is where I made

the decision to make it a painted steel material instead. That meant

I could colour the paint that duller, greyish blue like in the

reference. Also it meant I could chip the paint away in the mask

revealing the shiny steel underneath which would show some good

weathering.

I

then went about manually painting out the mask on the model. Making

sure the chipped and weathered parts were exactly where I wanted

them. I also filled in some of the areas which were too weathered and

made them painted once more.

Next

was for the blade and shiner steel parts. For this I added the same

material as the 'titanium' parts but I made the paint slightly

shinier. I then masked out all the paint on the sharp blade parts as

well as all the other steel areas like the diamonds and rivets to

make it purer steel to match the reference. I masked out a lot of the

other scuffed metal layer too, but kept some on many areas to keep

the steel from looking too clean, as it's clearly a very used sword.

After

some cleaning up of some parts I think it turned out really well:

Next

was to take it into Unreal. But first, I went back to Maya to my

original low poly and then hardened edges where I wanted them for

export as an FBX for Unreal. Now, as a disappointment to me, I didn't

really have enough time to learn Unreal properly and felt it's a

shame that I couldn't get it looking anywhere near as good in Unreal

as I could in Quixel (as you'll see). I set up as much as I could

learn within the time limit; some lights, some objects as a very

basic scene. I am looking forward to learning more of this in the

future because it's obvious that it's possible to get some very good

renders with more time available.

Here

is the final piece:

Things

I learned/Reflections on project

I learned a lot during

this project, from major organisational and decisions to small tips

and tricks. The first major thing I learned was to copy all the parts

first in Maya, like I mentioned before. I should have positioned all

the low poly pieces in the exact right place first, grouped it all up

then imported into zbrush together. Then I could have detailed all

the bits individually so; they would have been more unique and they

would also already be in the exact right positions so I wouldn't

need to do any extra work to the low poly – it would already be

there available to me when I need it later.

The next thing I learned

was to export full meshes (no holes) into zbrush. I thought I was

being clever by optimizing early, but instead it set off a whole

chain of problems. It meant that in zbrush I had gone up a bunch of

subdivisions and detailed, (and would have been too difficult to go

backwards) so I had to dynamesh to fill the holes. At the time I

thought this was ok, but it meant deleting the lower subdivisions on

the meshes which later on I needed. So in the future: no holes in

meshes, so I don't need to use dynamesh and can keep the lower

subdivisions in tact for when I may need them to export again.

As mentioned before, I

should have been more organised and made a copy of the low poly then

added edge loops of that copy and taken that into zbrush so when I

subdivided it would have kept the shape exactly how I wanted. This

way I keep my low poly completely optimized and in tact for the end,

and I still manage to keep the shape I want in zbrush.

Next was to make sure the

model in Maya is completely unified, centred with history deleted and

transformations frozen. I had a problem when trying to decimate in

zbrush at one point, because when I decimated the blade, it would

shrink and move it away from the wings part. This is because I had

imported the wings separately at the beginning to sculpt them. This

meant that they both had different origins and it created problems.

Next time I'll make sure I import everything I need together and in

the correct locations. It's amazing how many small problems can cause

knock on effects down the line.

Next thing was for UV's.

I should have unwrapped then copied each thing in Maya right at the

beginning when the low poly was first done. Not only that, but as

some of the pictures show, I have some same shells all layered on top

of each other. I figured at the time that because they were all

identical that it wouldn't be a problem, but that turned out not to

be true when baking maps. It was a problem. It meant I had to bake

some of the maps a few times as well as re-arranging some of the UV

sets to fit in the 0-1 space properly with no overlap at all. Also,

with the UV's I could have possibly tried to use less sheets, as I've

seen people get good results with larger models with many parts all

fit into the 0-1 space using a 4k map. In the future I may try that

regardless of how many parts I have.

Regarding zBrush, I

learned a couple of things. For instance it is very good for all the

larger parts and custom damage/wear like the chips and scratches on

the blade, but some of the smaller surface details can be left until

NDO/DDO. I think they are easier at applying them and is definitely

quicker to do so there rather than in zBrush. I also learned a few

other little tricks like how to create depth grabs for alphas, some

ways to export and also to merge subtools for exporting.

I learned a fair amount

about xNormal and how it reads UV's. I think in the future I will be

able to set up UV's in a much more sensible way to get the best bakes

from xNormal and minimise the considerable time it takes to bake some

of those maps. I also learned that 8k maps is completely unnecessary

after experimenting with one. I realised that 4k is sufficient for

almost all 'normal' sized objects.

I learned that if the low

poly object is good enough and accurate enough, decimation is

completely unnecessary as well. Saves time to be well organised

earlier on.

Other things I learned:

Quixel Suite 2 is amazing! So much more stable, I only had a couple

of crashes ever and it's so easy to make very high quality textures

with not much effort. I also got a pretty good feel for the PBR

workflow using it and editing masks etc. Also learned that Unreal

only imports RGB files so you have to save the greyscale files as RGB

anyway in Photoshop before trying to import into Unreal.

So in conclusion, I'm

fairly happy with the model overall. I think it looks really good in

Quixel. I'm really disappointed about how it looks in Unreal though.

I just didn't have the time to properly learn it very well to get the

most out of the PBR textures in the renderer I think. I was also

disappointed that the second brass I made looks a bit too much

plastic in the final version. It's annoying that the first one looked

so much better. Also adding to the Unreal render, there is something

weird with the roughness going on in Unreal. In Quixel, some of the

parts are completely matte almost, (and still are in the maps as you

can see in some of the above pictures taken from Quixel) but in

Unreal however, these parts are really shiny. Most of it worked fine,

there were just certain parts which haven't seemed to render properly

in UE4, the dark chunky bolts on the side of the blade are one of

them, and some of the blade noise is really rough looking when it

should be more transparent.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.